Thousands of shops can perform precision fab. If you want to stand out in the crowd, you have to do more than deliver quality parts on time. That is why we focus on service. From quote to delivery, we work hard to provide the best service. For example, we send a weekly report that shows what is going on with your part. If we are behind on your part, we report it with honesty. We won�t always get it right. But we will make it right. You don�t have to take us at our word; check out our customer feedback.

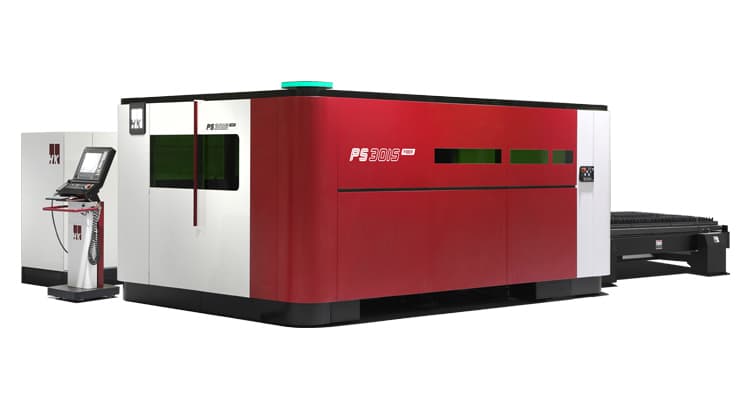

You can use them to build and assemble precision parts and components and to manufacture and assemble complex and precise line products. A large variety of products and applications is possible with our precision fabrication machines and some of them include: